Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management awarded a 10-year contract worth up to $45 billion to Hanford Tank Waste Operations and Closure (H2C) of Lynchburg, Va., to oversee the management of liquid radioactive tank waste at the DOE’s Hanford Site in southeastern Washington state.

Workers install one of 18 startup heaters into Melter 1 of Hanford’s Low-Activity Waste Facility. (Photo: Bechtel National)

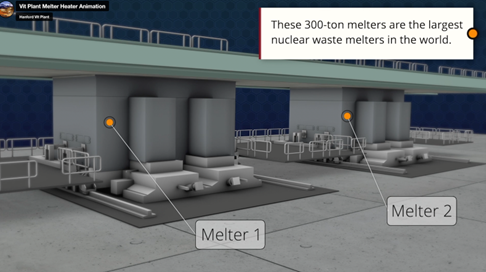

Heating of the first waste vitrification melter at the Department of Energy’s Hanford Site was paused after operators identified an “abnormal condition with the startup heater power supplies,” the DOE’s Office of River Protection (ORP) said. Heat-up of the 300-ton melter, which will be used to vitrify Hanford’s low-level radioactive tank waste, was initiated on October 8.

A screenshot from a 3D animation showing the heat-up of Hanford’s melters. (Image: DOE)

Crews at the Department of Energy’s Hanford Site, near Richland, Wash., have begun heating up the first of two 300-ton melters that will be used to vitrify mixed low-level radioactive and chemical tank waste. According to the DOE’s Office of Environmental Management (EM), initiating and completing the heating of the melter is a critical step to commissioning Hanford’s Waste Treatment and Immobilization Plant (WTP), which will treat and stabilize the site’s 56 million gallons of tank waste by immobilizing it in glass through the vitrification process.

The B Farm underground waste tank area at Hanford. (Photo: DOE)

Washington state’s Department of Ecology and the U.S. Department of Energy have agreed on a plan for how to respond to two underground tanks that are leaking radioactive waste, as well as any future tank leaks, at the Hanford Site near Richland, Wash.

In April 2021, following a year-long leak assessment, the DOE announced that Hanford’s Tank B-109 is leaking waste into the surrounding soil. Tank T-111 was discovered to be leaking in 2013. Currently, Tank B-109 is leaking about 1.5 gallons of waste per day, and Tank T-111 is leaking less than a gallon a day, according to the DOE.

Hanford workers will soon begin retrieving about 373,000 gallons of waste from Tank AX-101, shown here in an image from an inspection video shot. (Photo: DOE)

Washington River Protection Solutions (WRPS) is preparing to retrieve waste from Tank AX-101 at the Department of Energy’s Hanford Site near Richland, Wash. WRPS is the tank operations contractor at Hanford.

During the Hanford Site's Direct-Feed Low-Activity Waste Program treatment operations, the Waste Treatment and Immobilization Plant, background, will feed liquid waste to the Liquid Effluent Retention Facility, foreground, through a primary transfer line pictured here. (Photo: DOE)

Work crews at the Department of Energy's Hanford Site recently completed the first transfer of test water from the Waste Treatment and Immobilization Plant's Effluent Management Facility to the nearby Liquid Effluent Retention Facility (LERF). The transfer of 6,000 gallons was the first simulation of the process that will be used to treat secondary liquid waste from the plant’s Low-Activity Waste Facility during operations to treat tank waste.

“This is a tremendous accomplishment that culminates years of work by our team and alumni toward being ready for hot commissioning,” said Valerie McCain, project director and senior vice president for Bechtel National, Inc. “It’s an important step for the entire Hanford team and our collective mission of protecting the Columbia River and its shoreline communities.”

Bechtel National is a contractor of the DOE's Office of Environmental Management's Office of River Protection.

WRPS operations engineer Steven Porter, left, and nuclear chemical operator Brent Walker monitor the TSCR System in the control room as the system is put in operations mode. (Photo: DOE)

The Department of Energy announced on Wednesday that the first large-scale treatment of radioactive and chemical waste from underground tanks at the Hanford Site near Richland, Wash., has begun with the start of operations of the Tank-Side Cesium Removal (TSCR) System.

The newly operational TSCR System removes radioactive cesium and solids from the tank waste. The treated waste will be fed directly to the nearby Waste Treatment and Immobilization Plant (WTP) for vitrification when the plant comes on line next year.

A worker installing new waste transfer lines between Hanford’s large underground tanks and evaporator facility welds a secondary encasement on one of the lines. (Photo: DOE)

As the Department of Energy's Hanford Site prepares for around-the-clock operations for tank waste disposal, workers at the site's 242-A Evaporator are upgrading equipment used to remove water from the tank waste and the systems that transfer waste to and from large underground containers. The upgrades will also extend the evaporator’s service life.

Crews pump waste from Hanford’s single-shell tanks to more stable double-shell tanks. (Photo: DOE)

The Department of Energy is considering solidifying 2,000 gallons of Hanford’s tank waste and disposing of it as low-level radioactive waste at an off-site facility. A virtual public meeting on the proposed disposal plan is scheduled for November 18.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management (EM) has issued a final request for proposal (RFP) for the Hanford Integrated Tank Disposition Contract, a 10-year, $45 billion deal to oversee waste tank operations at the DOE’s Hanford Site near Richland, Wash. Proposals are due by December 20.

Hanford workers fit sections of double-walled pipe in place, connecting the site’s tank farms to the Waste Treatment and Immobilization Plant. (Screen shot: WRPS/YouTube)

The Department of Energy is celebrating a major milestone in its tank waste mission at the Hanford Site near Richland, Wash. DOE tank operations contractor Washington River Protection Solutions has finished construction of the pipeline that will carry treated waste from an underground tank to the Waste Treatment and Immobilization Plant (WTP) for vitrification.

The B Complex area tank farm at the DOE’s Hanford Site in Washington. Photo: DOE

The Department of Energy announced that it has determined that an underground single-shell waste tank at its Hanford Site near Richland, Wash., is likely leaking into the soil beneath the tank. The DOE said that the leaking tank poses no increased health or safety risk to the Hanford workforce or the public.

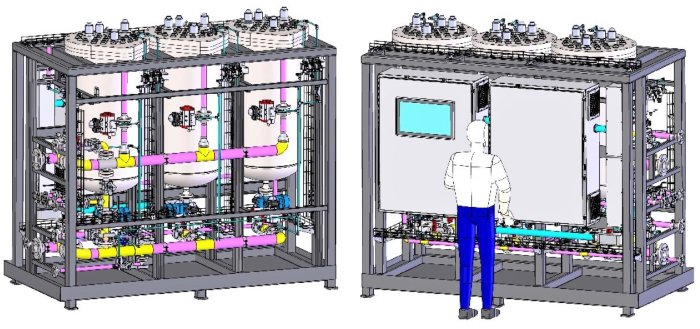

A front-and-back illustration of the new Hanford ETF filter system, which is intended to eliminate the need to shut down operations every 12 hours to replace filters during wastewater processing. Image: DOE

A new wastewater filter system being installed at Hanford’s Effluent Treatment Facility (ETF) is expected to increase waste processing throughput, improve efficiency, and save money as the site in southeastern Washington gears up to treat tank waste, the Department of Energy announced.